I should have stopped and restarted that print, but didn’t. The nozzle crashed through some already laid lines as it printed. Most recently for me, the rafts of two parts overlapped in several places.

I haven’t tried this yet.Why did the nozzle clog? In my case, an accumulation of clumsy abuse is most likely, like dropping the Z-axis harshly by turning off the power. It might be possible to salvage the old nozzle but heating it to filament melt temperature and then… clean it out somehow. I’m using the 0.2 mm nozzle while I wait for DHL to deliver the replacements. It will have a balled up clump of melt on it, which is what prevents it from withdrawing.Replace the nozzle. Push out the stump of wadded up filament, in the normal feed direction.

Cetus3d printer clean gear free#

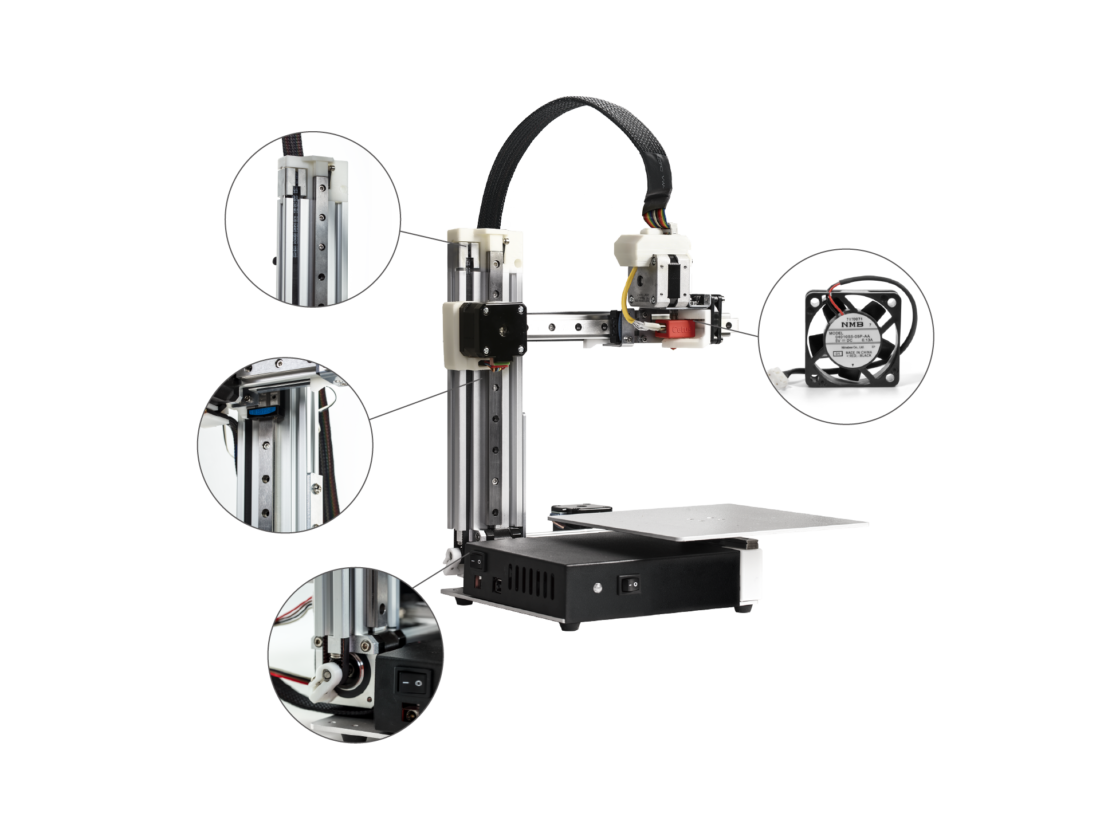

With the power off, the stepper is free to turn. Remove the nozzle using the lug wrench that came with the printer. You are unable to extrude or withdraw filament.Clip the filament with the wire cutter between the feeder and the nozzle riser. The feeder is able to turn freely, and so stops clunking but still does not feed. After a while, the filament is all chewed up, and nothing resists the feeder gear. The extruder stepper would try mightily, visibly flexing the feeder housing, and then fail by skipping a step, or stripping a chunk off the filament, each time making a loud “clunk”. the extruder would skip a step continually, making a noisy “clunk” as it does so. I had the same or similar problem a few days ago, same symptoms. If the fan is not properly cooling the upper steel part of the nozzle then there can be some filament melting and depositing along the upper walls of the nozzle.The diameter of the filament can also be an issue and if the filament is more oval than round there will be issues at the extruder.I’ll try and help you guys, let me know how things are going once you check for the above possibilities.cheers,BrentTechnology Salad I’m using a guide tube of 75mm’s (3inches) and feeding the filament to the guide tube with the least amount of resistance, you should be able to effortlessly pull the filament off the filament roll.You may have a problem with excess heat. The longer the guide tube, the higher the friction of the filament rubbing the walls of the guide tube and will make the motor sluggish by decreasing the available torque. Getting filament to the nozzle can sometimes be a pain and guide tube length can create problems if too long. I noticed in the vids you linked the first link has the filament guide tube installed in the provided holder and the second vid does not. Hi there,I’ve had my MKII for about 6 weeks now and have been 3D printing for over 5 yrs now.

0 kommentar(er)

0 kommentar(er)